Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Ms. Coraline

What can I do for you?

Ever wondered how metal parts achieve a polished, mirror-like finish? The key lies in choosing the right abrasive filaments. Let’s simplify this concept using everyday experiences like peeling potatoes and cleaning glasses.

Grit Size

Choosing Grit for Specific Tasks

Tips for Beginners

1. Layer Your Sanding: Start with 80 grit for burrs, then 180 grit for leveling, and finish with 320 grit for shine. This saves time compared to using only fine grit.

2. Select the Right Grit: Use 60 grit for deep scratches and 120 grit for shallow ones. The wrong choice can double your sanding time.

3. Wet Sand for Smoothness: Wet sanding prevents clogging and boosts brightness by 30%, similar to washing dishes with water.

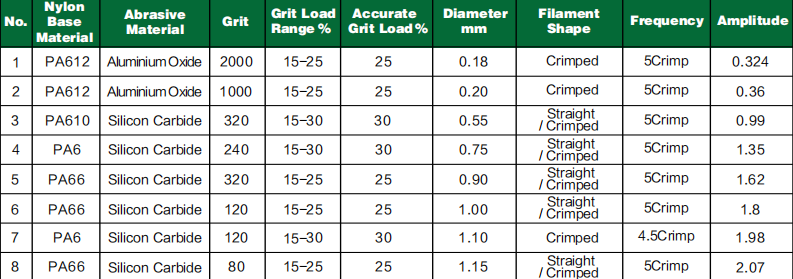

Tai Hing provides professional SIC/AO/DM/abrasive filaments for industrial brush manufacturing industry to carry out metal polishing/grinding/edge deburring/finishing tasks.

If you are intested in our abrasive fibers, welcome to contact us to get more details. Email:marketing@taihingnylon.com

Choosing the right abrasive filament is essential, whether for automotive parts or medical devices. Just as you use a coarse knife for peeling and a soft cloth for polishing, understanding this logic helps you decide whether a part needs rough treatment or gentle care!

The importance of hotel hygiene is not to be said. So, pay attention to a new broom: easy to do a good job in hotel hygiene, the broom surface is still clean! People who are always hygienic should...

How much is the ordinary broom? The broom is a cleaning tool that every family has to prepare. Do you know that the world’s first broom was invented by the Chinese? After a long period of...

How often do you wash your makeup brush? Do you have the habit of cleaning makeup brushes? In fact, many people still don't realize that makeup tools need to be cleaned regularly, otherwise they will...

Roller brush is a professional tool commonly used in decoration and decoration. The material is mostly engineering plastics and fibers, and natural wool fabric is also used. The roller brush is a...

Email to this supplier

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.